DTF Printing Transformation: Releasing Creativity in Fabric Style and Production

Wiki Article

The Future of Style: Exploring DTF Printing Modern Technology in the Textile Sector

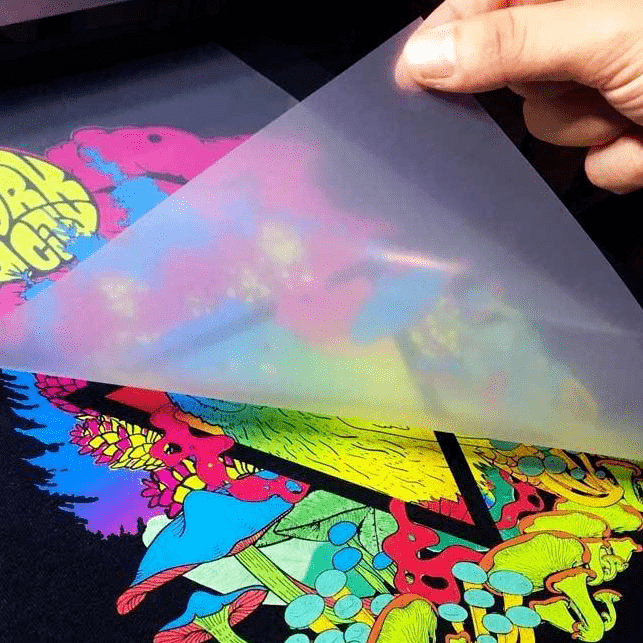

Amongst these developments, Direct to Movie (DTF) printing technology has actually arised as a promising contender, using one-of-a-kind capabilities and opportunities for designers and makers alike. This sophisticated printing approach has stimulated passion due to its potential to change conventional textile printing procedures.Advancement of Textile Printing

From the old civilizations making use of techniques like block printing to the electronic transformation of today, textile printing has consistently pressed boundaries. As the craft spread to various other components of the world, brand-new approaches such as screen printing and roller printing arised during the Industrial Revolution, changing the textile industry.

In the 20th century, advancements in modern technology resulted in the development of rotating screen printing, permitting faster and much more detailed styles. The introduction of electronic textile printing in the late 20th century noted a significant change towards even more sustainable and flexible printing methods. Today, with advancements like Direct-to-Fabric (DTF) printing technology, developers can create lively, detailed prints with higher performance and decreased ecological impact. The advancement of textile printing showcases a rich background of creativity, ingenuity, and technical development worldwide of style and design.

Benefits of DTF Innovation

With the advancement of fabric printing techniques from ancient techniques like block printing to contemporary technologies such as digital printing, the introduction of Direct-to-Fabric (DTF) innovation has substantially boosted the efficiency and sustainability of textile printing processes. One of the primary benefits of DTF technology is its capability to straight publish styles onto textile without the demand for transfer documents, which lowers waste and streamlines the production procedure. Additionally, DTF printing enables for higher shade vibrancy and information accuracy compared to standard approaches, making it possible for fabric suppliers to develop detailed and high-quality designs effortlessly.Furthermore, DTF technology is known for its flexibility, as it can be utilized on different types of materials, including natural fibers like cotton, wool, and silk, in addition to synthetic products such as polyester and nylon (DTF Printing). This versatility opens up a vast array of opportunities for developers and suppliers to experiment with various structures and materials, bring about even more cutting-edge and one-of-a-kind products in the garment industry. In general, the execution of DTF innovation stands for a considerable improvement in fabric printing, using many benefits that contribute to the future sustainability and imagination of the market

Sustainability in Fashion Production

Emphasizing environment-friendly methods is paramount in modern style production, straightening with the growing customer demand for lasting products. In recent times, the style market has actually faced raising scrutiny because of its significant environmental influence, including too much water usage, chemical contamination, and fabric waste. As a reaction, several fashion brands are currently incorporating sustainable methods right into their production processes to decrease harm to the atmosphere.Sustainability in style production includes numerous facets, such as using recycled and natural materials, decreasing power intake, implementing honest labor techniques, and promoting transparency throughout the supply chain. In addition, improvements in modern technology, Continue like DTF printing, offer chances to better enhance sustainability in textile manufacturing. This modern technology allows exact printing on textiles, lowering ink wastage and water usage compared to standard printing approaches.

Design Freedom and Personalization

Moreover, DTF printing assists in modification on a scale formerly unattainable, allowing for customized apparel and distinct items tailored to private choices. Overall, DTF printing innovation changes the design landscape in the fabric sector, offering limitless opportunities for creative expression and customized style.

Impact on Supply Chain & Market Trends

DTF printing technology in the textile sector is improving supply chain characteristics and influencing market trends through its performance and modification capacities. By allowing on-demand printing and eliminating the need for huge supplies, DTF modern check it out technology enhances the supply chain process.

Moreover, the modification potential of DTF printing innovation is revolutionizing the market patterns in the fabric industry. As a result, DTF modern technology is driving a shift in the direction of even more cutting-edge and customer-centric approaches within the fabric sector, shaping the future of fashion.

Final Thought

Finally, DTF printing innovation is changing the textile market by supplying numerous benefits such as layout sustainability, personalization, and liberty. This innovative innovation is improving the future of style production, impacting supply chains, and driving market patterns towards a lot more environment-friendly and reliable techniques. As the industry continues to develop, DTF printing will certainly play a crucial role in shaping the way textiles are produced and consumed in find this the years to come.From the ancient worlds utilizing methods like block printing to the digital transformation of today, textile printing has constantly pushed boundaries. As the craft spread to other parts of the world, brand-new approaches such as display printing and roller printing arised during the Industrial Revolution, revolutionizing the textile sector.

The intro of electronic textile printing in the late 20th century marked a substantial shift in the direction of more sustainable and versatile printing methods.With the development of fabric printing strategies from ancient approaches like block printing to contemporary innovations such as digital printing, the introduction of Direct-to-Fabric (DTF) modern technology has actually significantly boosted the effectiveness and sustainability of textile printing procedures (DTF Printing).In action to the crucial shift in the direction of sustainability in style production, the fostering of ingenious technologies like DTF printing not just addresses environmental problems however also opens up methods for unequaled design liberty and personalization in the fabric market

Report this wiki page